All the gear, all the time, dammit!

George Bernard Shaw perfectly captured the difference between optimism and pessimism. “An optimist,” said the famed Irish playwright, “invented the airplane; the pessimist the parachute.”

He could just as well have been talking about motorcycles and helmets. Of course, in any sport that suffers fools as little as motorcycling does, believing in the “worst of all possible consequences” is probably just being realistic. Whatever side of that psychological debate you fall on, however, we all want to know what gear offers the most protection if — a pessimist would say when — we get separated from our motorcycles.

The first question that needs answering is whether motorcycle gear really offers significant protection. Or are the fatalists riding GSX-Rs in t-shirts and flip-flops right: “Any high-speed motorcycle accident will probably be my last, so what’s the point in donning the modern equivalent of chain mail?”

The first thing that becomes obvious when researching motorcycle injuries is that high speed is not much of a factor at all. Though we are probably all guilty of a little gratuitous WFO throttle, such outbursts are underrepresented in motorcycle collision statistics. Indeed, most motorcycle accidents occur at surprisingly low speeds, 75 percent occurring at less than 50 kilometres an hour.

More importantly, according to a 2004 European study, Motorcycle Accidents In Depth (MAIDS), is that more than 40 percent of those get-offs see the rider simply sliding and/or tumbling down the road “without any further impact with another object.” Those crashes, says another study — Typical injury patterns of motorcyclists in different crash types — “are the types of crashes where protective clothing offers the greatest injury reduction.” In other words, while even the most modern riding gear can’t prevent injury from high-impact collisions with cars, telephone poles or any other object with more mass than your own self, anywhere from 40 to 50 percent of motorcycle crashes are survivable with little to no injury.

That is, if you are wearing the proper clothing. Two points dramatically illustrate the effectiveness of protective gear. The first is that in quantifying the damage done to victims’ head, arms, torso, legs and feet, the MAIDS study determined that in roughly 90 percent of these low-speed accidents, protective gear either completely prevented or dramatically reduced injury.

Equally telling was another study — Effectiveness of protective clothing in Munich area motorcycle accidents — detailing the recuperation time of the riders involved in motorcycle crashes. Hardly shocking is the authors’ conclusion that those wearing jackets and boots healed faster. But perhaps the difference might surprise you; those wearing leathers spent a week less in hospital and, more importantly, were 40 percent less likely to have suffered “permanent physical defect.”

That’s hardly a surprise; motorcycling-specific clothing should help prevent injury. What is a revelation is that none of these studies selected for specific types — or, more importantly, quality — of protective gear. In other words, the most crucial message of motorcycle safety is to wear something, anything, protective — yes, even that 10-year-old mesh jacket with the cheap Styrofoam padding that’s starting to disintegrate

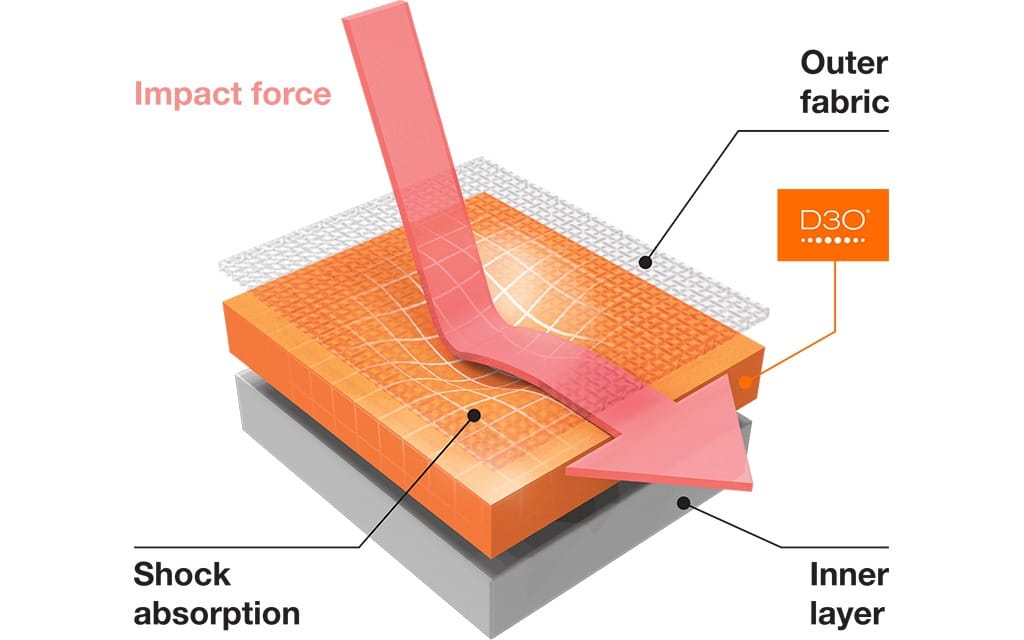

Nonetheless, it’s important to choose the best equipment. Here’s a primer on how protective gear works. The armour in motorcycle jackets and pants prevents injury by two methods of reducing impact: absorption and dissipation. Absorption is your basic sponge effect, the armour — foam or otherwise — collapsing and, in so doing, absorbing some of the energy of the blow. For illustration, let Mike Tyson punch you in the stomach with a Royal Hotel goose down pillow cinched around your waist; now try it without.

Dissipation is a much different mechanism. In this case, you’re not so much trying to blunt the force of the blow as to spread it out. Having someone hit you in the back with a hammer would seriously hurt; spreading the force of the blow over a much larger area would greatly reduce the pressure on any given bone.

Although that explanation is far too simplistic, it does help illustrate the difference between hard (typified by the stuff used in Dainese racing suits) and soft (Forcefield, D30, SAS-TEC and so many others) armour. As you might surmise, the very best protection comes from melding the two. That’s why Dainese hard armour comes with padding — to absorb what the outer shell does not dissipate — moulded into the back of its armour.

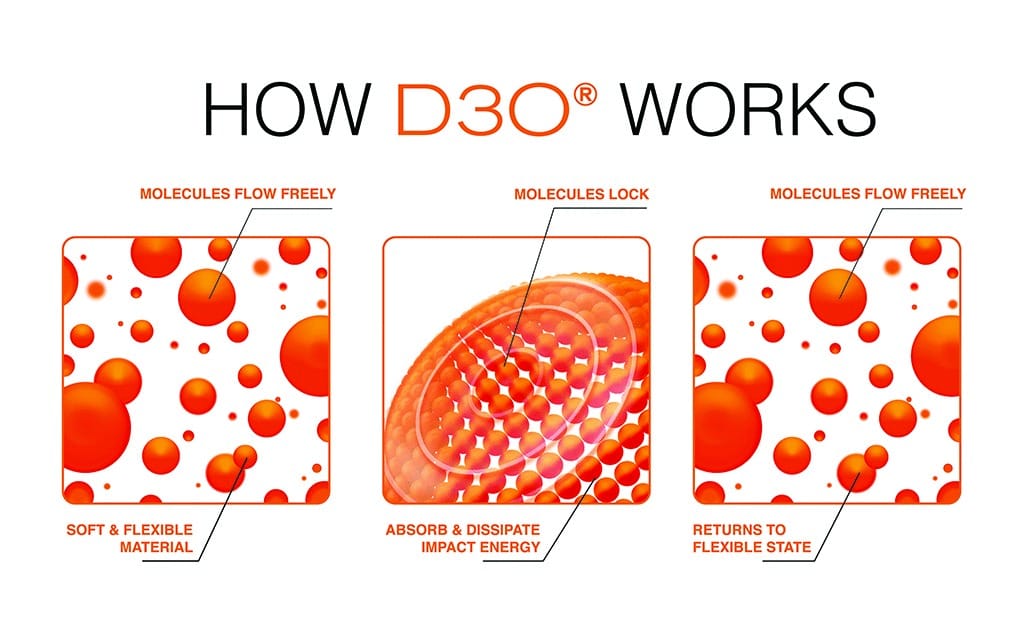

Meanwhile, the latest innovation in protection is viscoelastic armour — typified by the D3O, SAS-TEC and Aerostich TF brands — constructed from elastomers that can change their molecular structure under stress. As malleable as soft foam in normal circumstances, viscoelastic armour instantly gels into something far more rigid when struck a sharp blow, its change in molecular structure not only absorbing some of the blow but also dissipating some of the energy.

Still other systems — Rev’It’s SeeSoft, for instance — are built out of multiple layers of foam glued together. As the armour comes in contact with terra firma, those layers scrunch up against one another, thickening the effective protection layer for better cushioning.

So, how do you choose between these disparate technologies, let alone the manifold manufacturers hawking various versions of each? So far, the only differentiator between good gear and bad has been Europe’s Conformité Européene (CE) standard. Developed in the early ’90s as the result of the European Union’s Personal Protective Equipment directive, the first regulation, EN1621-1, set standards for energy absorption for shoulder, hip, knee and elbow protectors (there are also tests that set standards for abrasion resistance, impact-cut resistance and burst strength).

More well known, however, is the EN1621-2 standard for back protectors (and a corresponding 1621-3 standard for chest armour). All are further subdivided into two standards — the CE 1 and 2 labels you’re always told to look for — that offer increasing levels of protection. Much of Europe’s regulation of motorcycle protective gear, by the way, was inspired by the research of an English professor named Roderick Woods. The godfather of protective gear research, Woods was obsessed with how much blunt force trauma cowhide can endure.

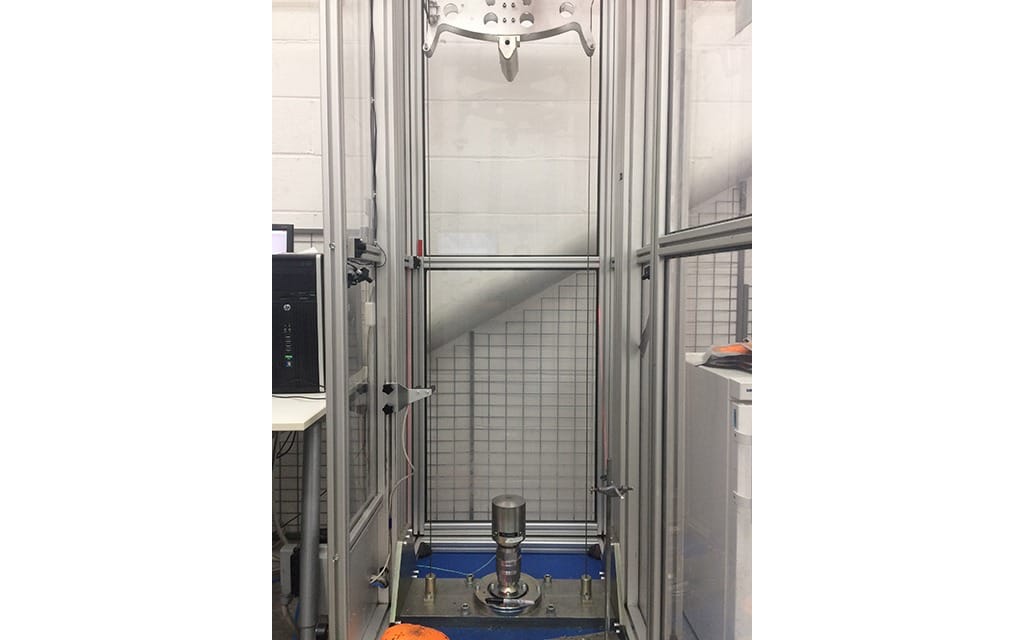

Essentially, the CE tests strike a piece of armour with a known amount of energy and then measures how much force is transmitted to the steel plate below. In the case of the EN1621-2 test, a five-kilogram triangular-faced prism with a 12.5-millimetre radius — to better concentrate the blow in one particular portion of the test back protector — is dropped one metre before striking an anvil with a 150 mm radius that is supposed to replicate your spine. For hip, shoulder, knee and elbow armour, the procedure is similar, only this time that five kg mass has a 40 mm x 30 mm striking face and is dropped onto armour mounted on top of a 50 mm radius hemispherical dome (the better to replicate smaller, knee, shoulder and elbow joints).

In engineering-speak, the amount of energy the anvil transmits to the armour is 50 Joules. To pass CE Level 1, shoulder, knee or hip armour must transmit no more than 35 kilo-Newtons of force through to the anvil below. To be certified as the more protective Level 2 gear, that maximum is reduced to 20 kN. Back protectors, meanwhile, are held to a higher standard and must allow no more than 18 kN to gain a CE 1 ranking while garnering the more stringent CE 2 certification requires that less than 9 kN must pass through to your back (or the steel anvil in the lab rig). However, manufacturers are under no obligation to publish their results: If a back protector is CE 2 certified, you know that it transmits less than 9 kN in those lab tests. How much less, you don’t know.

Currently, the most protective conventional back protector being sold — at least, the most protective I could find — is Forcefield’s Pro Sub 4 which transmits 3.38 kN through to the stress sensor/your spine. BMW’s viscoelastic NP back protectors, meanwhile, also score well below the CE 2 maximum with but 4 to 6 kN transmitted. Comparing the exact protection offered by armour, however, is impossible until all manufacturers are compelled to publish their actual results.

The problem with all that engineering mumbo-jumbo is that, unless, you’re a rocket scientist — or design motorcycle armour for a living — you probably have no idea what a Joule is. Or a kilo-Newton. Exactly how much energy does a Joule represent and what does a kilo-Newton feel like when it’s smacking you upside the ribs?

Officially, a Joule is a “unit of energy equal to the work done by a force of one newton acting through a distance of one meter.” A kilo-Newton, meanwhile, is the amount of force required to accelerate a one-kilogram mass at a rate of one metre per second squared.

That didn’t clear things up much, did it? How about this instead? Imagine someone dropping a five-pound brick onto your back from a height of about six feet. Or a 10-pound dumbbell from three feet. That’s about 50 Joules. Either could probably break bones. At the very least, either would be extremely unpleasant.

One more bit of perspective. “When the average rider is flying through the air at 60 miles per hour,” says Dr. Woods, he represents “something like 60 thousand Joules.” In other words, motorcycle protective gear is meant to protect a small portion of your body from the four or five miles per hour glancing impact that comes from falling off your motorcycle. In a worst case scenario, the best armour might also protect you from the slightly larger impact of a big highside. But, understand this: Even the world’s best armour will not blunt the impact of a 60 mph flight directly into a brick wall.

Exactly how much blunt force your body can endure is variable, but, according to biomedical researchers at Wayne University, it can take as little as three kN of force to crack an average person’s rib. Larger, more robust bones — your jaw, for instance — will take about twice as much impact before breaking — but nonetheless, it takes surprisingly few of those kN things to cause serious damage. Certainly, the 18 kN that a CE 2 back protector allows borders on the traumatic. And remember that 35 kN maximum for hip, shoulder and knee protectors to get CE Level 1 certification? It’s the impact at which bones start to shatter rather than breaking cleanly.

Just as important for all those who have yet to fall off their bike, what does getting smacked in the back by nine — or 18! — kN feel like? Research shows that a fair-to-middling middleweight MMA fighter can generate about eight or nine kN of force from a full roundhouse kick, a heavyweight boxer about the same from a good left hook. So imagine Mike Tyson connecting with one of his patented left uppercuts directly to your liver. That’s what that lab test says it would feel like if you’re wearing a back protector. And that’s with a more protective CE 2 protector, not one of the lesser Level 1 versions.

The problem with choosing armour only for its ability to ward off kilo-Newtons, however, is that protection is useless if it’s not worn. The best protection is the armour comfortable enough that you’ll wear every time you go riding. Unfortunately, this is not something that can be tested in a laboratory.

It is, however, where viscoelastic and other forms of pliable armour shine. The D3O armour so common in street-oriented protective gear these days is especially flexible, which dramatically improves comfort. Another comfort factor is venting, i.e., how much air the armour can pass to wick away sweat on a hot ride. Viscoelastic gear is generally not very well ventilated but other, matrix-style nitrile rubber items — like Rukka’s RPV-Air — are both flexible and let a significant amount of cooling air pass through. The point is, of course, that different armours suit different purposes.

In the end, the kind of protection you need depends on when, where and how you ride. That Forcefield Pro Sub 4 that shines so brightly in the CE tests is, despite being malleable, a bit of a bulky beast. It’s hard to believe that it’d be comfortable on a long tour. A better choice for street gear might be Forcefield’s own Pro L2K EVO, which also passes CE 2 tests but is far thinner.

Dainese’s hard armour, meanwhile, is extremely protective and energy absorbent, but some versions use an aluminum honeycomb to absorb energy. It’s effective, but only once. Once it is crushed, it can absorb no more. Forcefield, D3O and pretty much everyone who manufactures soft armour, meanwhile, stresses that their products, being built of pliable polymers, can absorb repeated blows. Dainese has upgraded some of its hard armour with a plastic, energy absorbing matrix that can withstand repeated knocks. And the company also has produced its own brand of Pro Armour “soft” armour, which it fits into jeans and other street-oriented garments.

Most articles detailing the abilities of armour refuse to make specific recommendations. And rightfully so: There are so many variables (no motorcycle accident is ever quite like the last), so much that is unknowable (the relative performance of protectors is not known) and there is so much variance in armour technology that making blanket recommendations is simply beyond the scope of even the most expert of scientists.

But I can tell you how I purchase riding gear. If I am racing, I wear a Dainese back protector; I like hard armour’s ability to dissipate as well as absorb and, on a racetrack, I’m less worried about its ability to withstand multiple impacts. The other choice is Forcefield’s Sub 4, which might not fend off a concentrated blow — e.g., a sharp curb — quite as well but probably offers more cushioning. Its extra protection is well worth buying looser leathers.

For the street, the first thing I do after I buy a jacket is replace all the armour with Forcefield Nitrex Evo gear or some form of viscoelastic armour, the choice being simply which fits the jacket’s pockets better. For instance, my prized Olympia Airglide 3 — an otherwise excellent mesh jacket that came with truly abysmal armour — has Forcefield Upgrade Performance Armour in the elbow, some D3O padding in the shoulders and an SAS-TEC CE 2 viscoelastic piece cut to fit in the back protector pocket. If venting is as important as pliability, then something like Rukka’s RVP-Air, might be more comfortable. It’s up to you which is more important — protection or comfort. Whatever the case, kits are available — an upgraded back protector will set you back between $40 and $100; elbow and shoulder protectors even less — so there’s no excuse not to retrofit your clothing with the best armour. Simplifying the process is that there is some universality of sizing in shoulder and elbow armour pockets.

One last aspect of protective clothing seldom discussed is how it conforms to your body. Every expert contacted for this article stressed that just as important as armour’s ability to absorb energy is how well said protectors fit the body. Just as automotive seat belts’ most important function is to keep passengers in position so the air bags can provide their cushioning protection, it is absolutely imperative that your armour fits snugly to your body so that it is in precisely the right spot when you hit the ground.

According to professor Woods, the most frequent injuries among motorcycle riders who were wearing protective gear were to the elbows, caused by loose jacket sleeves allowing elbow protectors to move out of position. My motorcycle clothier of choice, John McBride of Riders Choice, says the biggest problem he faces in selling racing gear is customers “wanting to buy suits one and even two sizes too big.” The suit he sold me — that I wear to this day — felt uncomfortably tight the first two times I wore it. Ditto for street gear: When I remove my Airglide’s two inner liners — rain and thermal — I cinch the arm straps tight so those Forcefield elbow protectors can do their stuff.

For the ultimate in precision, if not impact protection, nothing beats a body armour suit like the Pro Pants and Shirt combination by Forcefield, the Bodyguard system by Bohn or Leatt’s 3DF AirFit Body Protector. Indeed, topflight armour fitted to a skintight body suit so it’s always in the right place would seem to be the Holy Grail of passive armour. The downside is that these undergarments can feel a little like a sweat lodge when the thermometer hits 30 degrees. Like everything about motorcycle gear, despite their optimized protection, they too are a compromise.

The future of motorcycle protective gear, however, is not higher tech armour, but air bags. Air bags — fitted to jackets or as standalone vests — offer the best combination of hard and soft armour, their high pressure making the back protectors stiff enough to dissipate energy across a wide area but still soft enough to also absorb the blow. Dainese claims that the street version of its D-air system transmits but 2.5 kN — less than even that acclaimed Pro Sub 4 by Forcefield — in the EN 1621-2 back protector test. And remember that 35 kN CE 1 limit for knee, shoulder and elbow armour? When bones begin to shatter? Well, Dainese claims its D-air Racing air bag can reduce the force transmitted to your shoulder to just 2.0 kN.

Just as impressive is the claim by Clover (a boutique jacket brand from Italy) that its air bag — a huge affair extending from the rider’s coccyx almost to the top of the helmet — transmits but 1.4 kN in CE back protector testing. That is, according to Clover, six times better than what’s required for level 2 traditional back protectors and, perhaps more importantly, a reduction in impact of 35 times. In other words, if you fall on your back wearing an air bag-equipped Clover jacket, less than 3 percent of the impact force is going to reach your spine. Remember that Mike Tyson punch to the liver? This is a slap by a five-year-old in pigtails in comparison.

As an avowed pessimist, I just got my first air bag jacket.